CNG compressor station, including mother station, daughter station, and standard station. A CNG compressor station is a complete system designed to compress, store, and dispense compressed natural gas (CNG) for vehicles or industrial use. It includes key components like CNG gas compressors, drying systems, and dispensers. Ideal for fueling stations, these systems offer turnkey solutions with high efficiency and safety.

| Component | Function | Description |

|---|---|---|

| CNG Gas Compressor | Compress natural gas | High efficiency, low noise, multi-stage compression |

| Drying System | Remove moisture | Enhances gas quality, prevents corrosion |

| Control Panel | Intelligent control | Automated operation, remote monitoring |

| Storage Vessels | Store compressed gas | High-pressure storage for continuous fueling |

| Dispenser | Fueling vehicles | Compatible with multiple vehicle types, fast fueling |

| Skid-Mounted Structure | Modular design | Easy installation, compact footprint |

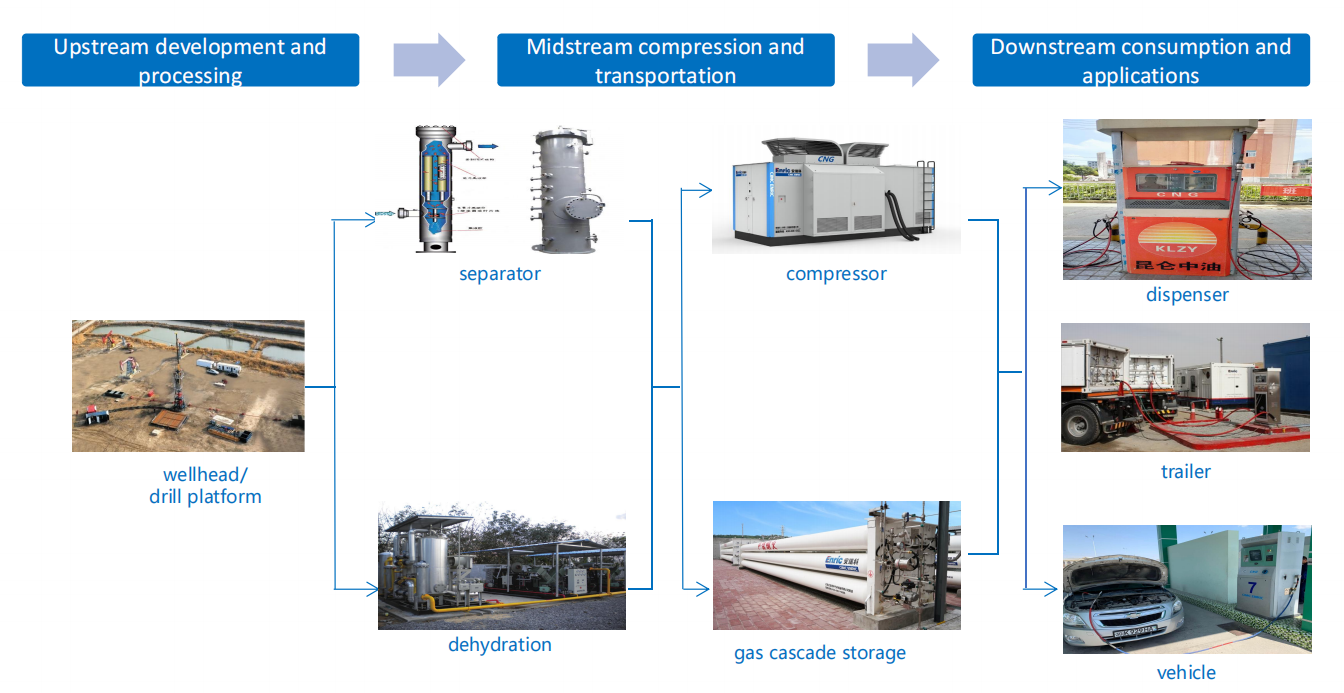

Natural gas utilization

Ideal for large-scale gas refueling centers or industrial gas supply, CIMC ENRIC mother station CNG compressors feature high flow rates (up to 500 Nm³/h) and stable pressure output (25 MPa). Equipped with water-cooled systems, they operate efficiently even in continuous working conditions, reducing energy consumption by 15% compared to standard models. The skid-mounted design allows for easy installation and space-saving, while the intelligent control system enables remote monitoring and automatic fault alarms—perfect for high-demand industrial environments.

· Working Principle: The driver drives the flywheel of the compressor through a coupling, which in turn drives the crankshaft to rotate. The connecting rod and cross - head convert the rotary motion of the crankshaft into the reciprocating motion of the piston. The piston makes a periodic reciprocating linear motion in the cylinder, causing the working volume of the cylinder to change cyclically, compressing the gas to increase its pressure to the rated gas pressure.

· Process System: It includes an intake filtration, pressure - regulating, and metering device, a desulfurization tower, a low - pressure dehydration device, a piston - type compressor, a sequence control panel, a gas storage cylinder bank, a gas dispenser, a gas - filling column, a CNG trailer, and a gas alarm device.

· Features: It is of an integrated skid - mounted type, which is convenient for installation and maintenance. It runs smoothly with low vibration. Due to the low rotational speed of the unit, the wearing parts have a long service life and low - noise operation. It adopts a pressure - lubrication system to ensure the reliable operation of the compressor. The unit is equipped with a PLC control system, featuring a high degree of automation. It uses international - brand gas valves with a long service life and low noise.

· Selection Range: The flow range is 0.05 - 200m³/min, and the pressure range is 0.1 - 25MPa.

Designed for mobile refueling scenarios (e.g., bus depots, construction sites), CIMC ENRIC child station CNG compressors are compact, portable, and easy to transport. These compressors integrate seamlessly with mobile refueling trucks, providing fast refueling for vehicle fleets without compromising on safety or performance.

· Working Principle: The common crank - connecting rod - type reciprocating piston compressor converts the rotational motion of the motor into the linear motion of the piston through the crankshaft, connecting rod, and cross - head to compress the gas. There is also a hydraulic - type compressor that uses hydraulic oil to drive the piston, converting hydraulic energy into gas pressure energy.

· Process System: Natural gas is input by a tanker, and after being pressurized by the compressor, it is directly filled into CNG vehicles or stored in a fixed gas storage cylinder bank for later filling.

· Features: It adopts an innovative segmented intake design technology. It features intelligent control and can operate unattended. It can be designed and manufactured with various displacement and pressure variations according to different customer requirements. The flow rate is 400 - 2200 Nm³/hr, and the inlet pressure range is 3.0 - 20MPa. It has cooling methods such as air - cooling, water - cooling, and hybrid - cooling. The installation methods include trailer - mounted mobile type, sound - proof shelter type, and fixed type.

· Advantages and Disadvantages: Compared with the connecting - rod - type compressor, when the hydraulic - type compressor is used in the daughter station, it is energy - saving under the medium - and high - pressure intake working conditions, with a low operating cost. It is small in size, has fewer components, and is simple to overhaul and maintain. It has low vibration and the noise is easy to attenuate, with high safety. However, the connecting - rod - type compressor has a mature technology and is widely used.

A versatile solution for medium-scale gas stations and small industrial facilities, CIMC ENRIC standard station CNG compressors balance performance and cost-effectiveness.

· Working Principle: Similar to the mother station compressor, it compresses and pressurizes natural gas through the reciprocating motion of the piston in the cylinder.

· Process System: It includes a pressure - regulating and metering device, a desulfurization and dehydration device, a natural gas compressor, a CNG gas storage facility, a sequence control device, a CNG gas - filling facility, a field safety and explosion - proof protection device for the gas - filling facility, an electrical control device, and CNG pipelines and components.

· Features: It is of an integrated skid - mounted type, which is convenient for installation and maintenance. The compressor is of a symmetrical - balanced type, running smoothly with low vibration. Due to the low rotational speed of the unit, the wearing parts have a long service life and low - noise operation. It adopts a pressure - lubrication system to ensure the reliable operation of the compressor. The unit is equipped with a PLC control system, featuring a high degree of automation.

☑ Bus company fleet refueling

☑ Natural gas transportation company

☑ Industrial natural gas compression

☑ Refueling mother station/substation construction

☑ LNG to CNG application